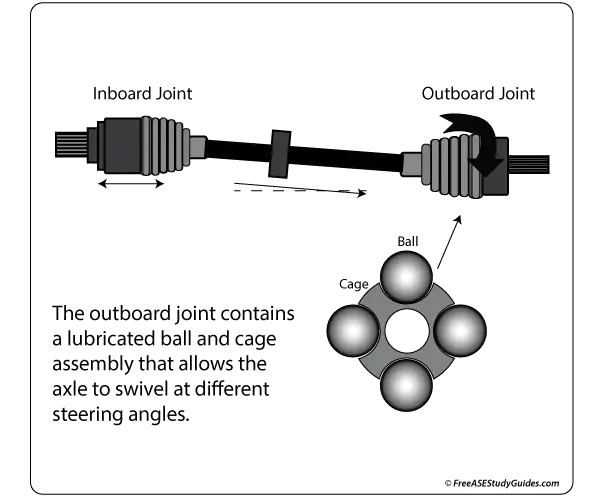

In front-wheel drive cars, ball-type CV joints are used on the outer side of the drive shafts (outer CV joints), while the tripod-type CV joints are mostly used on the inner side (inner CV joints). CV joint problems. The CV joint boot looks OK. Click for a larger photo. A CV joint is packed with special grease and sealed tight with a rubber or.. Front-wheel drive vehicles have drivetrains with two constant-velocity joints per half shaft. There is an inner constant-velocity joint and an outer constant-velocity joint. The inner constant-velocity joint is near the transaxle. The outer constant-velocity joint is near the wheel. If you are driving a rear-wheel drive vehicle, the inboard.

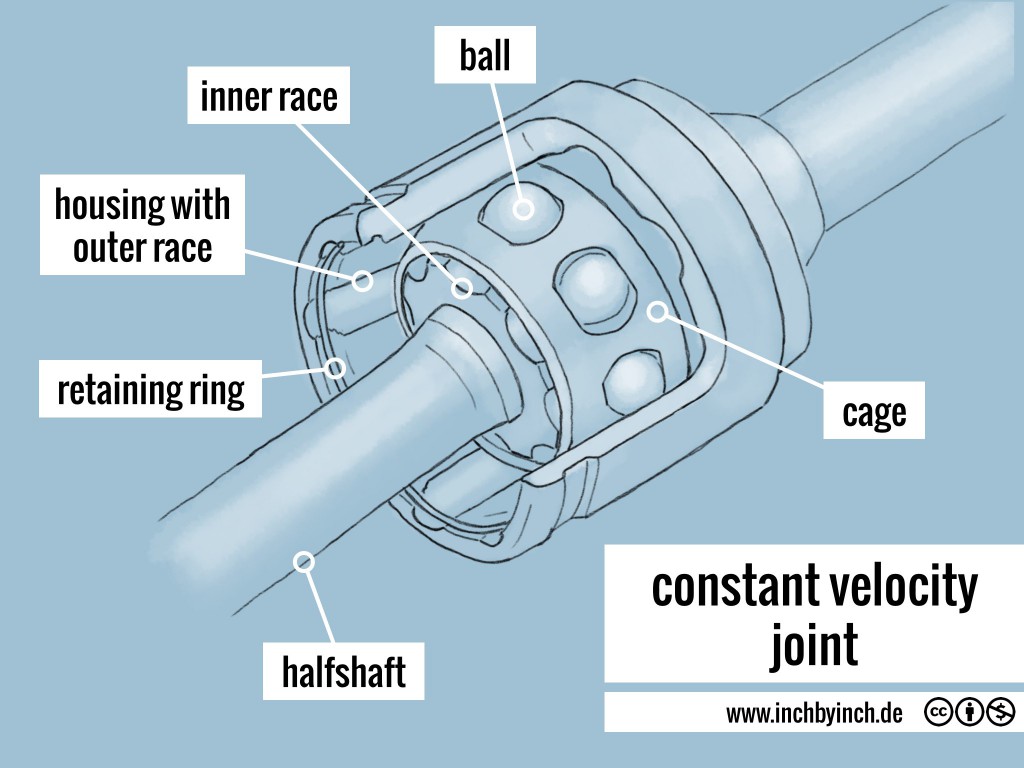

INCH Technical English pictorial constant velocity joint

Drive shaft with constant velocity joints 6C0407272CX

Constant velocity joint (SFT.80°) CV Series for PTO drive shafts Manufacturer, Supplier, Factory

Lightweight constant velocity joint

Drive shaft with constant velocity joints 6C0407272C

CV Joint Diagnosis

Set Drive shaft joint on white background. New Constant velocity joints, hub nut and retaining

Drive shaft with constant velocity joints 1K0407271PF

How a CV (constant velocity) axle works, Rzeppa joint simulation YouTube

Drive shaft with constant velocity joints 1K0407271PF

APDTY 043413 CV Joint & Boot Kit (Front DriveShaft PropellerShaft Front Joint), CV (Constant

Drive shaft joint on white background. New Constant velocity joints. Constant velocity joints

Walterscheid GmbH Massey Ferguson MF RB 4160V

Drive shaft with constant velocity joints 1K0407271PF

Constant Velocity Joint Thomas Performance

8K0501203K driveshaftwithconstantvelocityjointsdriveshaftwithcv Drive shaft with

Constant Velocity Drive Shafts Machine Service, Inc.

propshaft supply Drive Shaft transmission propeller shaft for jeep shaft NINGBO HOHAN AUTOPARTS

Set Drive Shaft Joint on White Background. New Constant Velocity Joints, Hub Nut and Retaining

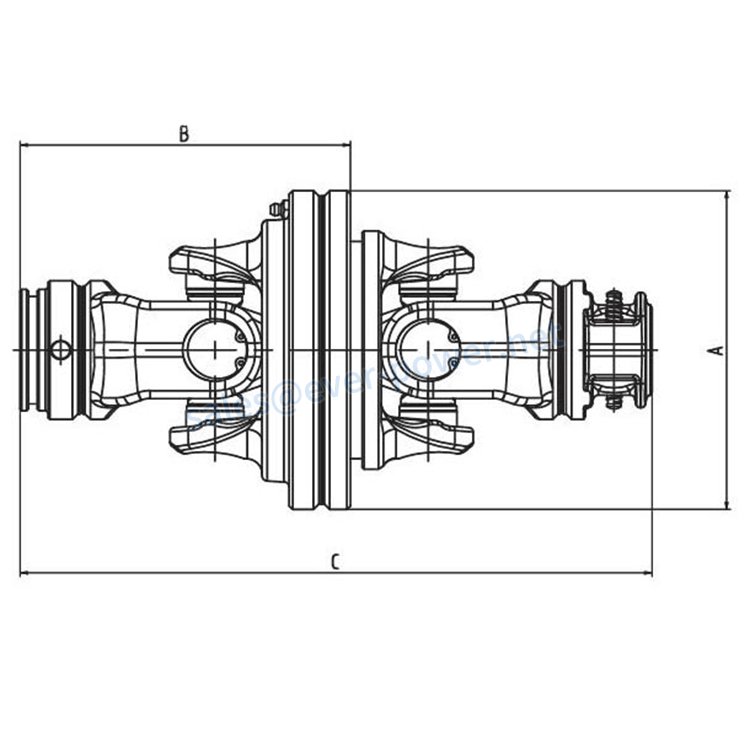

CV Joint Drive Shaft What is it and How it Works • D S Auto

Constant Velocity Joints (CVJ) Today’s CVJ systems require increasing performance capabilities, such as high rotational forces, thermal stress, corrosion, intense shock, vibration.. • Enhanced reliability, process-control. Oetiker revolutionized clamp products on early driveshaft systems and we continue to offer advanced connection.. Two constant velocity joints, one on the wheel side, the other on the differential side, allow the same rotational speed between input and output shafts, whatever the position and angle of the joints are in. The size of the joints and the length of the driveshaft depend on the vehicle design and the torque levels to be transmitted