Welding is a critical process in various industries, ranging from automotive to construction, requiring precision and accuracy. One of the often-overlooked tools that can significantly enhance the quality of welding is the welding ground magnet. This article explores how welding ground magnets improve welding quality, their functionality, and why they are essential for both novice and experienced welders.

What is a Welding Ground Magnet?

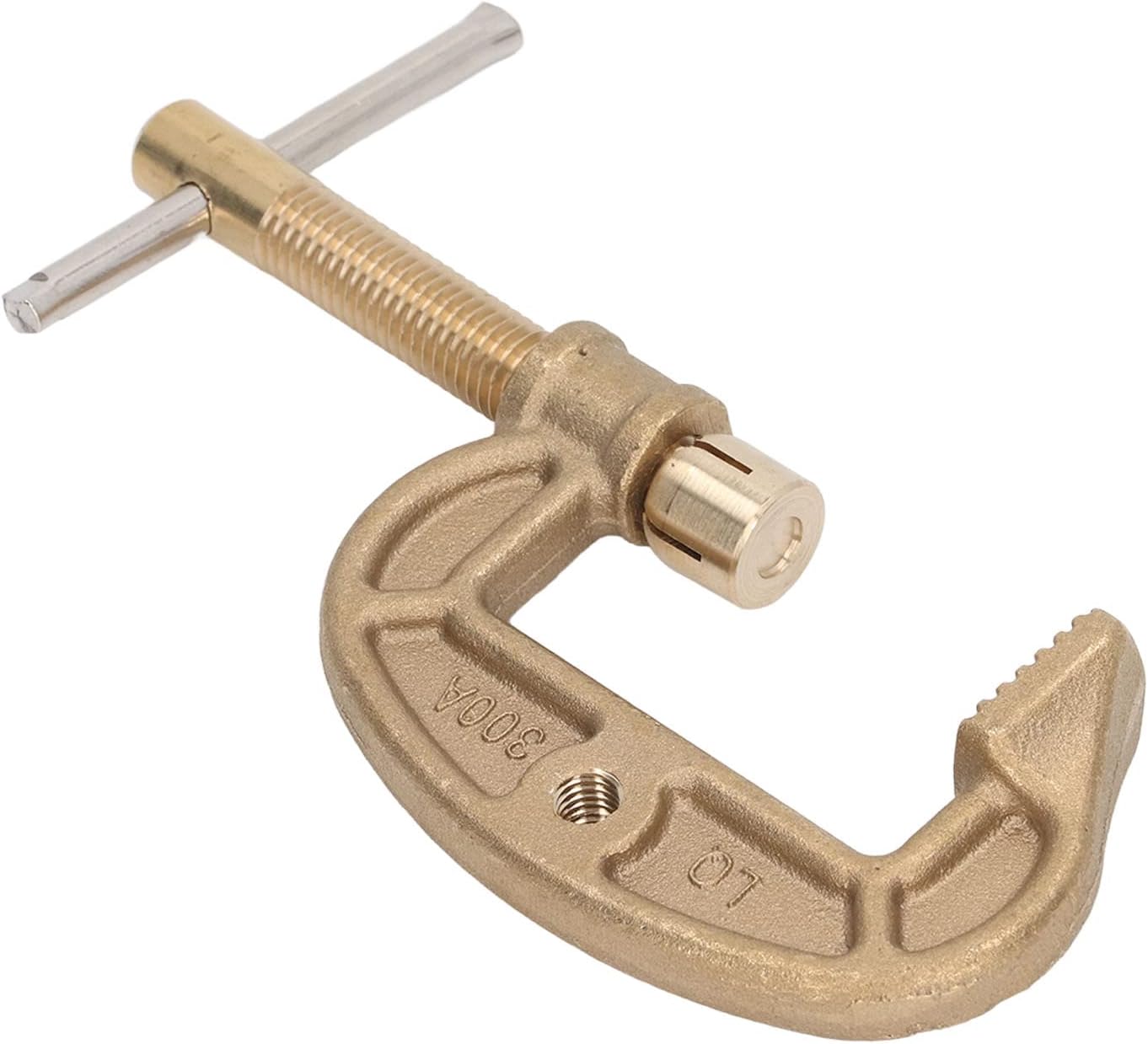

A welding ground magnet is a device designed to securely hold metal workpieces in place during the welding process. It is typically made from strong permanent magnets and is used to provide a stable grounding point for the welding arc, ensuring better electrical conductivity and improved stability. Ground magnets come in various shapes and sizes, making them versatile tools for different welding applications.

How Welding Ground Magnets Work

The fundamental principle behind welding ground magnets is magnetic attraction. When a magnet is placed on a ferromagnetic material, it creates a strong bond that holds the material in place. This is particularly beneficial in welding, where movement can lead to misalignment and defects in the final product. Here’s how they function:

- Magnetic Force: The strong magnetic force ensures that the workpieces remain fixed during the welding process, preventing any unwanted movement.

- Ground Connection: Welding ground magnets provide a direct electrical connection to the workpiece, facilitating effective grounding for the welding arc.

- Versatility: They can be used in various orientations, including horizontal, vertical, and even at angles, accommodating different welding scenarios.

Benefits of Using Welding Ground Magnets

Incorporating welding ground magnets into your welding setup offers numerous benefits that directly influence the quality of welds. Here are some key advantages:

- Improved Precision: By holding workpieces securely in place, welding ground magnets minimize the risk of misalignment, leading to more accurate welds.

- Enhanced Stability: The stability provided by magnets allows for better control over the welding arc, resulting in cleaner and more consistent welds.

- Time Efficiency: Setting up the welding process with magnets is often quicker than clamping methods, reducing overall preparation time and increasing productivity.

- Reduced Defects: By maintaining proper alignment and grounding, welding ground magnets help to reduce defects such as porosity and undercutting in the welds.

- Increased Safety: The ability to secure materials quickly and efficiently can reduce the risk of accidents associated with loose or unstable workpieces.

Real-World Applications and Case Studies

Numerous industries benefit from the use of welding ground magnets. Here are a couple of case studies that highlight their impact:

Case Study 1: Automotive Manufacturing

In an automotive manufacturing plant, welders were struggling with the alignment of chassis components due to the complexity of the structures. After incorporating welding ground magnets, the team noticed:

- A 30% reduction in misaligned welds.

- Decreased setup time by 15%, allowing for faster production cycles.

- Improved overall weld quality, leading to fewer rework hours and reduced scrap material costs.

Case Study 2: Construction Industry

A construction company specializing in metal framework relied heavily on welding for structural integrity. By using welding ground magnets, they achieved:

- Enhanced stability during the assembly of large steel beams.

- A 50% decrease in the time taken for initial setup, which allowed for more efficient project timelines.

- Higher quality welds, reducing the need for inspections and repairs.

Choosing the Right Welding Ground Magnet

Not all welding ground magnets are created equal. Selecting the right one for your specific needs is crucial for maximizing their benefits. Consider the following factors when choosing a welding ground magnet:

- Magnetic Strength: Ensure that the magnet’s strength is sufficient for the thickness and type of metal you are working with.

- Size and Shape: Depending on your application, choose a magnet that fits the dimensions and geometry of your workpieces.

- Portability: For mobile welding applications, consider lightweight and easy-to-carry designs.

- Durability: Look for magnets made from high-quality materials that can withstand the rigors of welding environments.

Best Practices for Using Welding Ground Magnets

To maximize the benefits of welding ground magnets, follow these best practices:

- Clean Surfaces: Ensure that both the magnet and the workpiece surfaces are free of debris, rust, and contaminants for optimal magnetic adhesion.

- Proper Placement: Position the magnet strategically to provide the best grounding and stability without obstructing the welding arc.

- Regular Maintenance: Inspect magnets regularly for wear and damage and clean them to maintain their magnetic strength.

Welding ground magnets are invaluable tools that can significantly enhance welding quality across various industries. By providing improved precision, stability, time efficiency, and safety, these magnets help reduce defects and enhance overall productivity. As demonstrated through real-world applications, incorporating these devices into your welding processes can lead to remarkable improvements in the quality of your work.

In summary, whether you are a novice welder or a seasoned professional, investing in a welding ground magnet is a step toward achieving superior welding outcomes. With careful selection and proper use, welding ground magnets can transform your welding experience, ensuring high-quality results that meet industry standards.